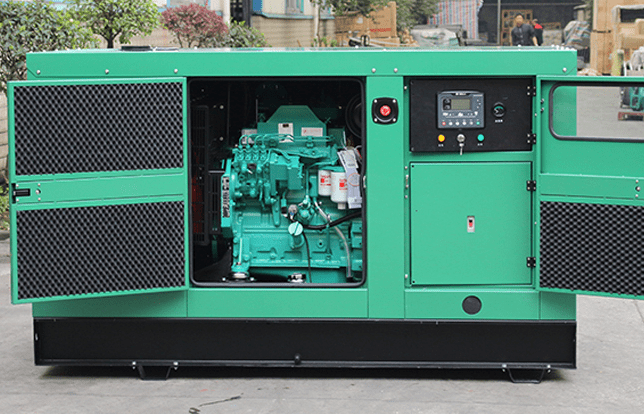

How to Maintain a Generator

Buying a diesel generator for your home or business use is a significant achievement. It takes effort and proper maintenance to keep it working.

Here are eight essential things to guide your diesel generator maintenance:

- Carry out regular checks

- Keep the generator clean

- Top up the fluids

- Remove and replace worn out parts in good time

- Check the fuel system and exercise the engine

- Keep the batteries charged

- Keep the control panel safe

- Check the exhaust system for leaks

A diesel generator set comes with its maintenance manual. Some manufacturers recommend an oil change and service at 500 hours of operation.

Some units might need servicing at less than that. The manufacturer might also include after-sale service as part of the package. So, go to the website of your generator manufacturer and find out what they offer.

Follow the steps below to keep your generator working in good condition all the time:

1. Carry out Regular Checks

Checking your diesel generator often lets you see problems as soon as they occur.

Diesel generators have many moving parts. Thus, they need regular monitoring, especially when they run often. Check the DC (direct current) electrical system for peeled cables. Also, check the fuel system, engine, and exhaust system for leaks.

If it’s been some time since you used the generator, it is imperative to check the cables for damage. You can also check the battery because it might refuse to fire up.

Even when you are not using the generator, start it daily if possible. Let’s run for a few minutes and then switch it off.

When you perform a routine check, keep a log of the most vital stats of the generator. For example, note the oil level, the coolant, and the ease of starting. That way, if you notice an anomaly in the next check, you will know something is amiss.

2. Keep the Generator Clean

If dust and grease cover the diesel generator, you will not spot any leaks, cracks, holes, and other issues.

Thus, keeping your GenSet clean makes your regular inspection moments easier. It will be easy to spot any worn-out belts and other parts. If you pay no attention to the generator for too long, rodents might find their way in and chew the plastic piping.

If you don’t use your generator daily or weekly, you can cover it to prevent dust from inside. That way, you will not need to clean it too often.

3. Top up the Fluids

A diesel system has two main parts that help in generating power. These are the engine and the generator. They have many moving parts, like vehicle engines.

The generator uses fluids such as lubricating oil, coolant, and fuel. Watch the levels of these critical fluids and top them up when you need to.

For oil, use the provided dipstick to check the level. You must keep the oil level at the recommended greatest. To top them up, only use the products that the manufacturer recommends.

Also, look out for these fluid leaks and if you spot any, let a technician repair any broken pipes. If there are lids that need replacement, get them immediately.

To check the cooling system, you need to let the generator cool down completely. Actually, it is best to check all the fluids when the engine is cold.

Open the radiator cap and inspect it to see whether there is any solidified matter under the cap. If there is, it could mean that the gasket is burning out.

If the radiator cap is okay, check the coolant level. Usually, this is a mixture of antifreeze, water, and other additives.

The quantity of the coolant in the radiator must always be at the recommended level. If it goes lower, check for leaks. Even the most minor leaks can drain the radiator.

4. Remove and Replace Worn Out Parts in Good Time

Regular checks on your diesel generator set will reveal worn-out parts. If you find a domain that needs replacement, get a professional technician to do the job.

Even if it is one of the simplest parts, such as a fan belt, if showing signs of wear and tear, replace it immediately.

When some parts wear out, they might stop the operation of the generator. Some might even affect other parts.

Other parts that wear out include the charge air hose pipes. When left in disuse, they can develop cracks and start leaking. Besides, debris can get inside the lines, and then the generator will suck it all in.

Check the pipes for blockages too. Inspect the connections and tighten any clips that might have gone loose.

5. Check the Fuel System and Exercise the Engine

The first thing is to check the ground around the generator for diesel fuel spillage. If there is none, you can move on to check other things, such as the fuel filter at the recommended interval.

Even if the generator has not been running, you need to check the fuel system for leaks. Drain the fuel filters at the intervals that the manufacturer recommends.

The importance of draining them is because water vapor condenses in the fuel tank with time. You should also use or replace the fuel in the tank within six months.

For some generators, the manufacturer might recommend replacing the fuel every three months.

Exercising the engine means giving it a run for about 30 minutes every month if you do not use it often. Also, you should run it under a third of its full load. You can check the most oversized load rating of your generator.

Running the engine prevents rusting of metal parts. Oil can circulate throughout the engine.

Besides, running it for a considerable time of 30 minutes can let you know of any troubles. You can then call a technician to repair the generator. When the need to use it arises, it will start without hiccups.

6. Keeping the Batteries Charged

Routine testing of the batteries will let you know when they are dwindling. That way, you can ensure that the batteries keep their full charge.

But before you check the technical details like the voltage, keep the batteries clean. Wipe this with a damp piece of cloth.

Check the terminals for signs of corrosion. If there is any, clean it with a cloth dipped in a water and baking soda solution.

That will not only clean it, but it will keep the terminals from corroding again for some time. Remember to apply a light coating of petroleum jelly on the terminals to keep them rust-free.

When there is a power outage, you want the generator to start without any difficulties. When the batteries are low, the generator will not start in good time.

Some things that you need to check-in batteries include the output voltage. Also, check the voltage of the batteries under load to get the most accurate terminal voltage.

If your batteries are old, they will have more internal resistance to current. It is best to test them under load.

There are two ways to test the voltage of the batteries under load. First, find out whether the generator tests voltage when you start it. If it does not, you have to use a manual load tester.

If your generator uses lead-acid batteries, check the electrolyte level every 200 hours. If you find that the status of the electrolyte is low, refill the battery with distilled water.

7. Control Panel Maintenance

Ensure that the control panel display is always clean. Before you start the generator, ensure the control panel is set on “Auto” mode. If it is not, the generator might refuse to start.

Keep the control panel safe from falling objects that might crack the LCD display. Also, wipe it with a piece of soft cloth so that you can read the displayed information.

8. Check the Exhaust System

After running the generator for some minutes, check the exhaust system for leaks. If you spot any, it means that there is a leak somewhere. Exhaust system leaks happen along the welded joints.

Also, check the kind of smoke that the generator produces. Usually, if it bellows thick and black smoke, it could sign worn-out parts in the fuel system.

Conclusion

The eight tips we have brought you here will help you to keep your generator in top condition.

A frequently-used generator needs more care, attention, and maintenance. If you hardly use yours, a few casual inspections a month should be enough.

The most important thing to do is to follow what the manufacturers recommend in the manual. Take care of the most vital things. Such as batteries, cooling systems, fuel systems, and fuel change.

If you give it good care and maintenance. You can enhance your diesel generator’s lifespan a great deal.